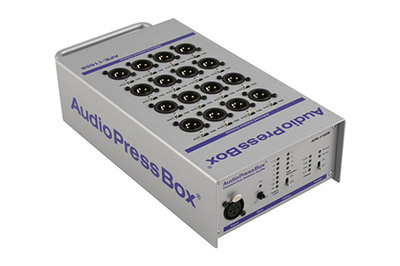

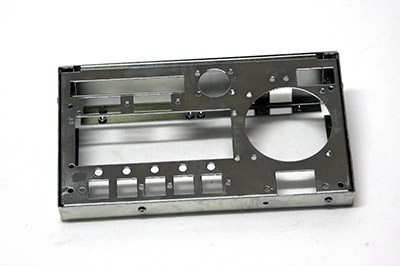

Complex services in the field of sheet metal processing such as:

-

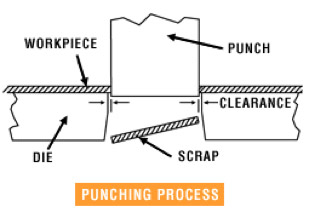

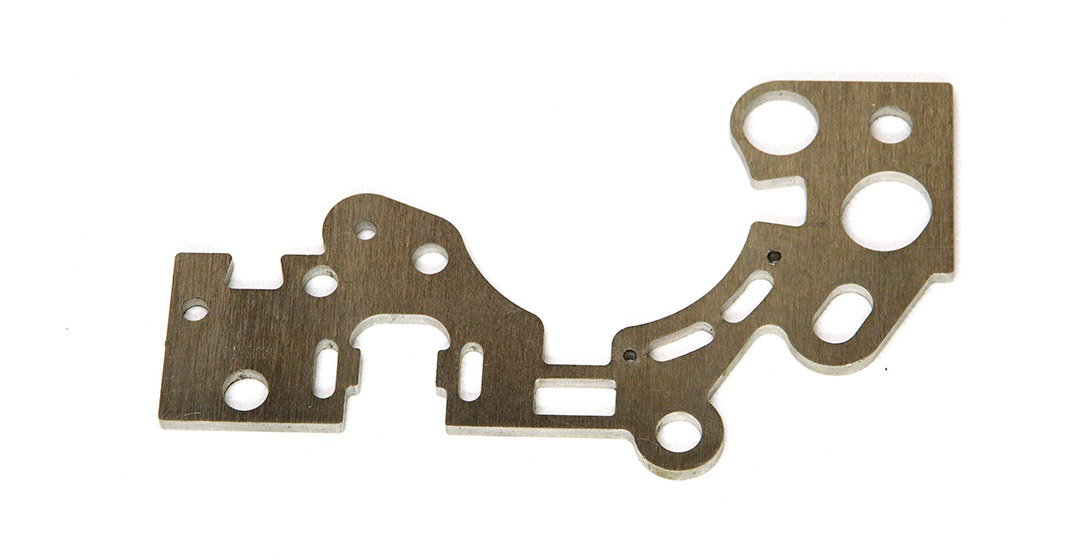

Punching is a metal fabricating process that removes a scrap slug from the metal workpiece each time a punch enters the punching die. This process leaves a hole in the metal workpiece.

Characteristics of the punching process include:

- Its ability to produce economical holes in both strip and sheet metal during medium or high production processes.

- The ability to produce holes of varying shapes - quickly.

The punching process forces a steel punch, made of hardened steel, into and through a workpiece. The punch diameter determines the size of the hole created in the workpiece.

The illustration that follows provides a two-dimensional look at a typical punching process. Note how the workpiece remains and the punched part falls out as scrap as the punch enters the die. The scrap drops through the die and is normally collected for recycling.

Punched material is most normally in sheets with outside dimension:

1000x2000m

1250x2500m

Maximum Sheet Thickness/Gauge

We can punch metals up to 0.5mm – 3.0mm.

Tonnage

Advantage Fabricated Metals' punching maschine have tonnage capacities up to 30 tons.

Materials Punched

We punch the same standard materials that we stamp. Commonly punched materials include:

- Aluminum (All Alloys)

- Brass

- Cold Rolled Steel

- Copper

- Galvanized Steel

- Hot Rolled Steel

- Zinc

Equipment

During the time we extended our machines equipment.

Punching machines:

EUROMAC ZXR 1250/30 CNC Max. Punching Force (kN) 300

Table dimension X = 4000mm Y= 2200mm Working area axis X = 2000 mm with reposition 10 000mm Working area axis Y = 1300 mm Axes positioning accuracy: 0,05mm Maximum number of strokes ca.: 700 1/min Maximum sheet thickness: 3,0mm steel / stainless steel 1,5mm Maximum tools diameter 76,0 mm Punching head with Trumpf tools EUROMAC ZXR 1250/30 CNC Max. Punching Force (kN) 300

Table dimension X = 2500mm Y= 1300mm Working area axis X = 1250 mm with reposition 10 000mm Working area axis Y = 750 mm Axes positioning accuracy: 0,10mm Maximum number of strokes ca.: 200 1/min Maximum sheet thickness: 3,0mm steel / stainless steel 1,5mm Maximum tools diameter 76,0 mm Punching head with Trumpf tools EUROMAC ZXR 1250/30 CNC

Max. Punching Force (kN) 300 Table dimension X = 4000mm Y= 2200mm Working area axis X = 2000 mm with reposition 10 000mm Working area axis Y = 1300 mm Axes positioning accuracy: 0,05mm Maximum number of strokes ca.: 700 1/min Maximum sheet thickness: 3,0mm steel / stainless steel 1,5mm Maximum tools diameter 76,0 mm Punching head with Trumpf tools EUROMAC ZXR 1250/30 CNC

Max. Punching Force (kN) 300 Table dimension X = 2500mm Y= 1300mm Working area axis X = 1250 mm with reposition 10 000mm Working area axis Y = 750 mm Axes positioning accuracy: 0,10mm Maximum number of strokes ca.: 200 1/min Maximum sheet thickness: 3,0mm steel / stainless steel 1,5mm Maximum tools diameter 76,0 mm Punching head with Trumpf tools -

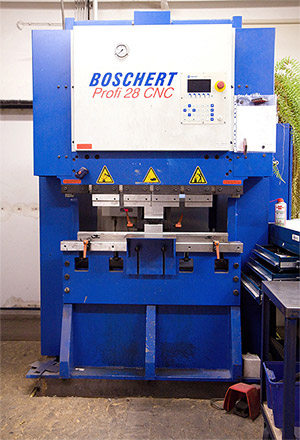

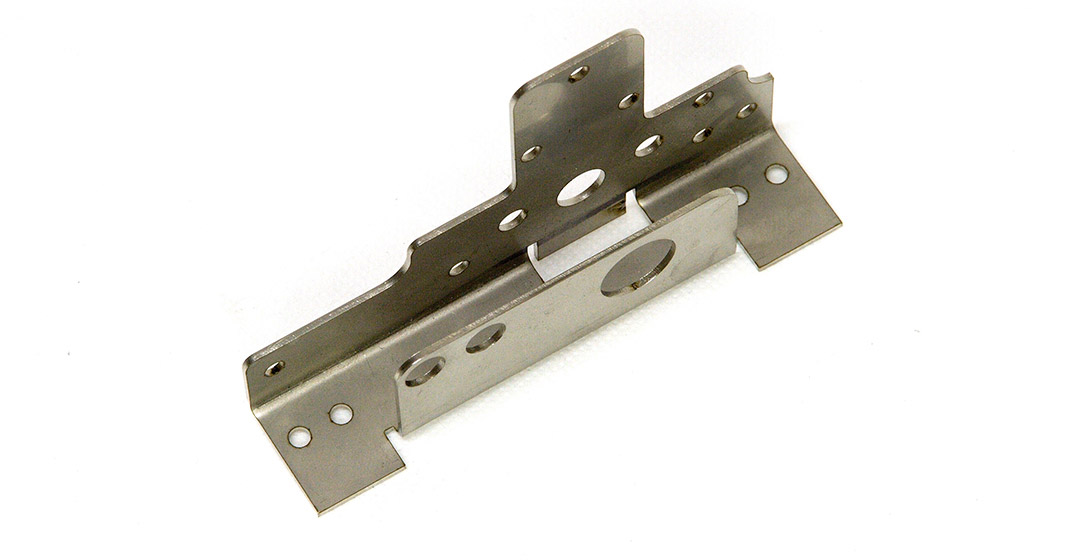

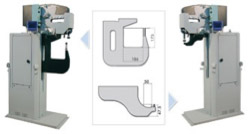

Press braking is a metal forming process that uses an open-frame single-action press used to bend, blank, corrugate, curl, notch, perforate, pierce, or punch sheet metal or plate. To view details about our press braking services:

Tonnage

Advantage Fabricated Metals' press brakes have tonnage capacities up to 28 tons.

Gauge

Our press brakes are capable of forming metals up to 0.5mm (air formed).

Materials

We press brake the same standard materials that we stamp.

- Aluminum (All Alloys)

- Brass

- Cold Rolled Steel

- Copper

- Galvanized Steel

- Hot Rolled Steel

- Zinc

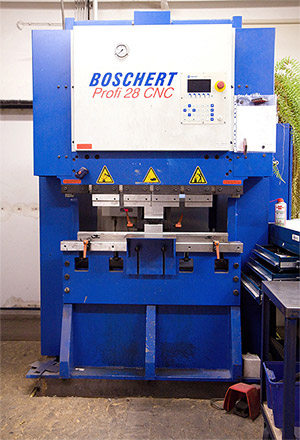

Boschert Profi 28 CNC Bending force 280 kN

Bending length 1000 mm Weight 3000 Kg Distance between the frames 890 mm Throat depth 200 mm Daylight 305 mm Y-Travel 200 mm Max. stop range in X 370 mm Repeatability +/- 0,02 Control Labod / Cybelec Vesip Hol-28/850 Bending force 280 kN

Bending length 850 mm Weight 880 Kg Distance between the frames 850 mm Daylight 250 mm Y-Travel 100 mm Max. stop range in X 350 mm Repeatability +/- 0,05 Boschert Profi 28 CNC

Bending force 280 kN Bending length 1000 mm Weight 3000 Kg Distance between the frames 890 mm Throat depth 200 mm Daylight 305 mm Y-Travel 200 mm Max. stop range in X 370 mm Repeatability +/- 0,02 Control Labod / Cybelec Vesip Hol-28/850

Bending force 280 kN Bending length 850 mm Weight 880 Kg Distance between the frames 850 mm Daylight 250 mm Y-Travel 100 mm Max. stop range in X 350 mm Repeatability +/- 0,05 -

Laser cutting works by focusing the power of a high-power laser onto the surface of the material to be cut. The energy in the laser beam is absorbed into the surface of material, and the energy of the laser is converted into heat, which melts or vaporizes the material. Additionally, gas is focused or blown into the cutting region to expel or blow away the molten metal and vapor from the cutting path.

There are two possibilities for laser cutting material:

- with Oxygen

- with Nitrogen

Laser cutting material is most normally in sheets with maximum outside dimension: 1250x2500mm

Maximum sheet thickness/gauge of materials:

- Aluminum (All Alloys) up to 1,0 mm – 8.0mm

- Cold Rolled Steel up to 1,0 mm – 3.0mm

- Hot Rolled Steel up to 3,0 mm – 20.0mm

- Galvanized Steel up to 1,0 mm – 4.0mm

-

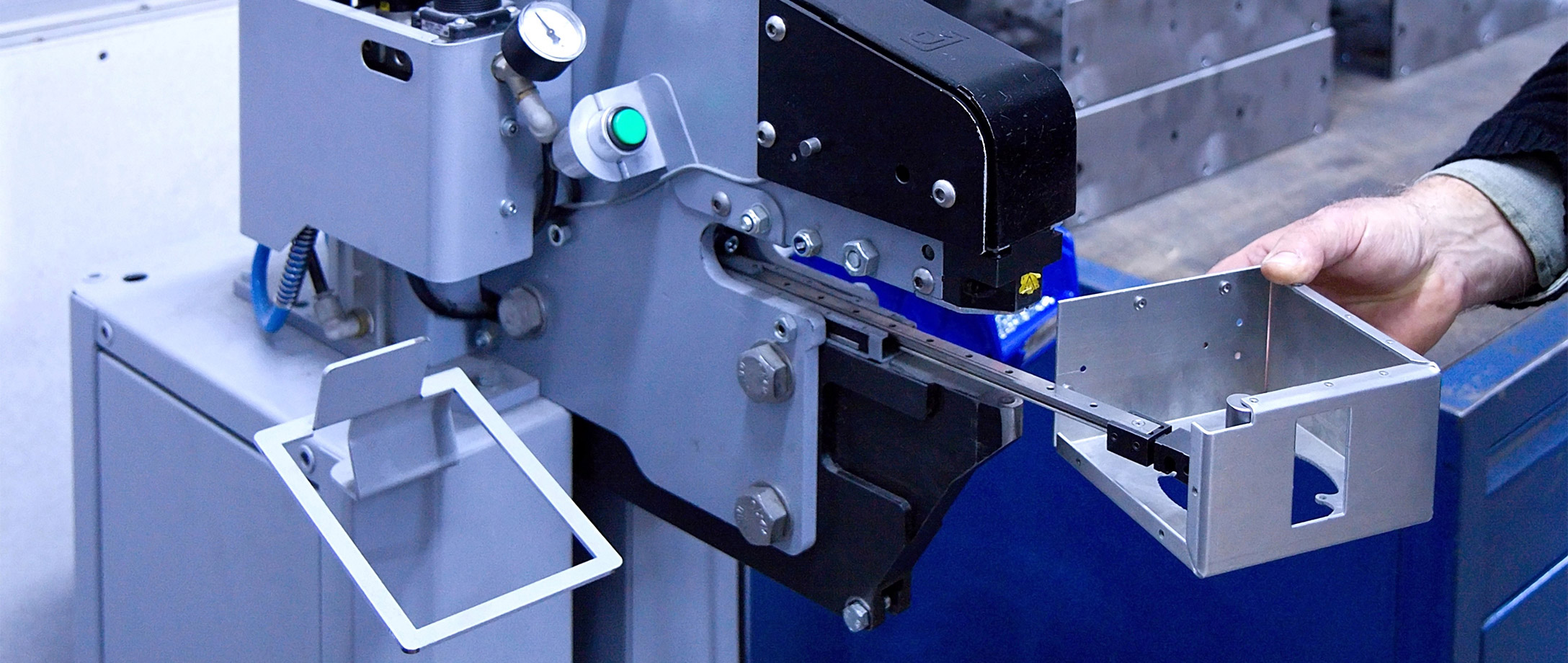

LCM Prima

LCM Prima is a fastener-installation equipment capable of self-clinching, broaching, flaring, surface mount and utilizes weld technology to provide strong, reusable, and permanent threads and mounting points in thin sheet metal, P.C. board materials, and other ductile or non-ductile thin material.

DOWNLOAD :: Catalog of pressing elements

-

Welding is the process of permanently joining two or more metal parts, by melting both materials. The molten materials quickly cool, and the two metals are permanently bonded. Spot welding and seam welding are two very popular methods used for sheet metal parts.

Advantage Fabricated Metals' welding staff has decades of complex welding experience. Our skilled welding staff provides a full range of welding services. We can provide welding services ranging from structural and plate welding to light gauge tubular steels, stainless, and aluminum.

We jig and fixture components to be welded to ensure parts are correctly aligned before being joined providing quality and repeatability.

We provide:

TIG (Tungsten Inert Gas)

MIG (Metal Inert Gas)

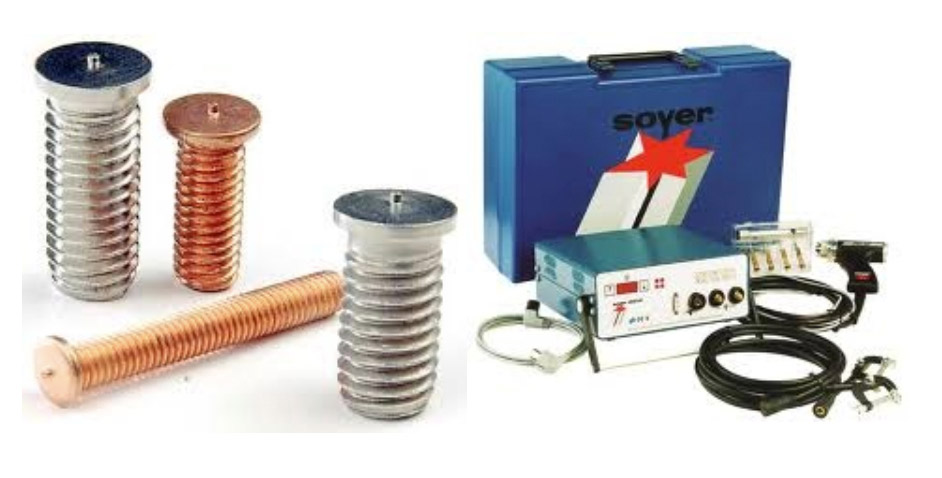

Stud welding is a complete one-step fastening system, using a wide variety of fasteners called weld studs. In this welding process a fastener can be end-joined to a metal work piece instantaneously for a high quality, high strength permanent bond.

This process is less expensive than other fastening methods and can used in locations which do not allow the use of other fasteners. Weld Studs can be installed by one man, working on one side of the work piece.

-

Powder coating is a type of coating that is applied as a free-flowing, dry powder.The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin". Powder coating is mainly used for coating of metal cases and aluminium extrusions.

Surface treatment, powder varnish (komaxit) according to RAL or Phantone

-

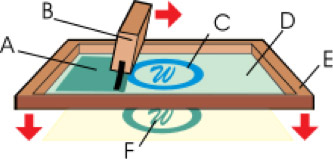

Screen printing is a printing technique that uses a woven mesh to support an ink-blocking stencil to receive a desired image . Printing colors are according to RAL or Phantone.

- A. Ink

- B. Squeegee

- C. Image

- D. Photo-emulsion

- E. Screen

- F. Printed image